Company Profile

Precision Metal Fabrication Specialist

About Us

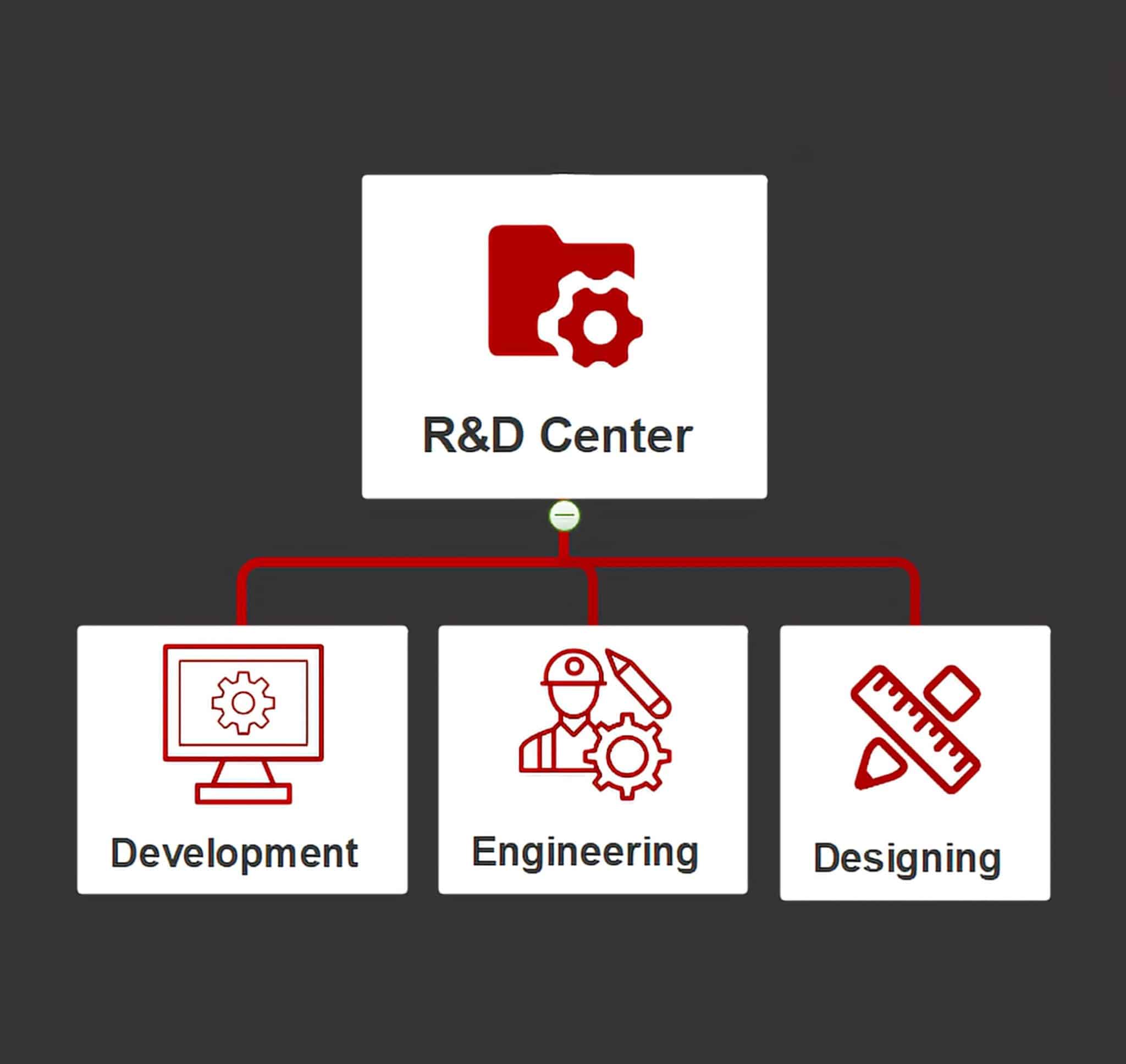

Since our establishment in 2009, we have been a dedicated precision die and stamping production factory based in China. With a diverse clientele spanning industries such as Automotive, Healthcare, Machinery, Consumer Electronics, Power Supply, New Energy, etc. we have consistently strived for excellence in providing high-quality products and services. Over the years, we have grown to a team of over 150 professionals with an average age of 38. Among them, we are proud to have 30 highly skilled individuals in research, development, and design, driving technological innovation.

Our Mission

Customers

Delivering top-quality products and services in precision mould manufacturing, ensuring customer satisfaction through excellence and innovation.

Personnel

Fostering a culture of growth and care, enhancing working conditions, and promoting shared development.

Society

Committing to social responsibility, prioritizing community welfare, sustainable practices, and ethical business conduct for a positive impact.

Our History

2009

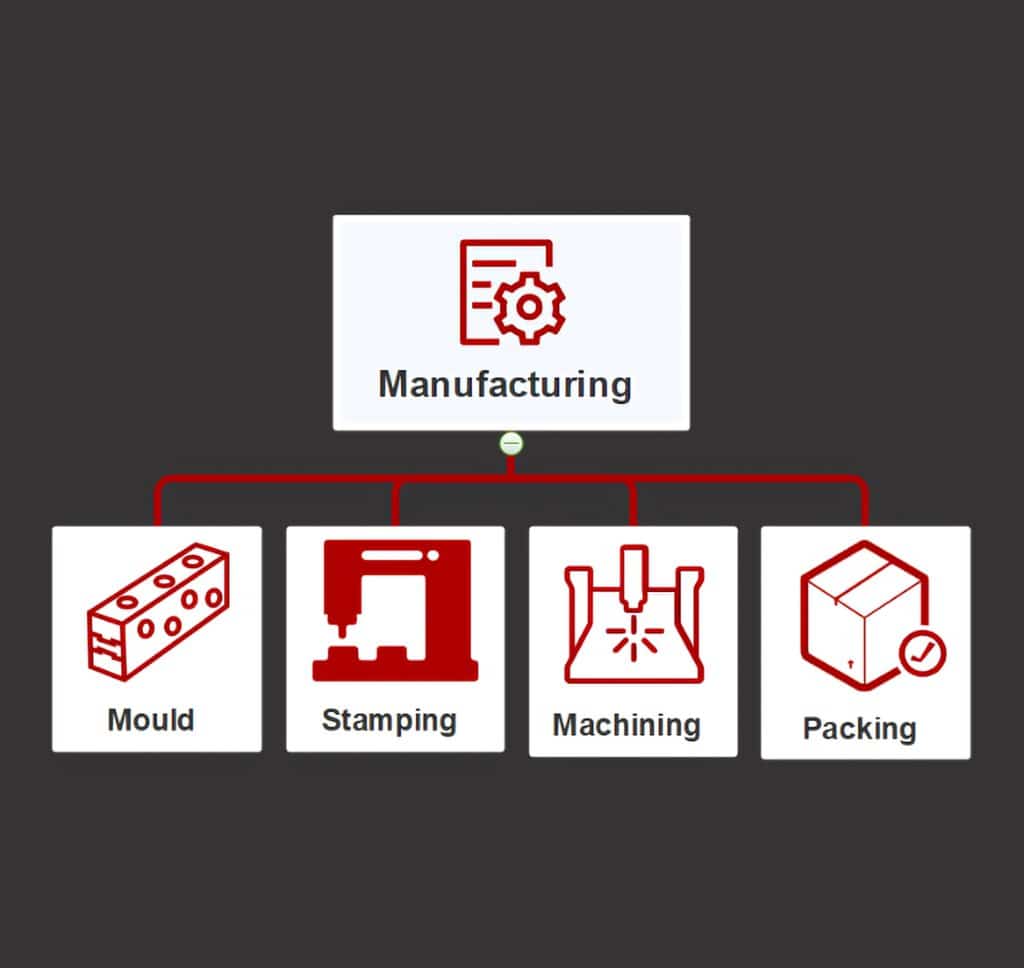

The company was established, and the main business is precision mould parts processing(EDM & CNC).

2013

Set up the mould division with the main business: the design, processing, assembly and debugging of the whole set of stamping moulds, and proofing.

2015

Established a stamping business department and participated in the Apple PAD computer project

2018

Developed and undertook the Inovance industrial control frequency conversion copper and aluminum bar project.

2019

Increased capital and expanded production to establish Jiangsu PenJing Technology Co., LTD., expanding stamping production lines and multi-process processing.

2020

Developed and undertook the Volkswagen air conditioning compressor gasket project.

2020

Developed and undertook the General Motors engine cylinder pad project.

2021

Developed and undertook the Tesla motor copper bar project.

2021

Established the injection moulding division.

2021

Developed and undertook the project of Apple computer cooling module, meanwhile, put into the automatic stamping production line.

2022

Developed and undertook the hydrogen energy reactor bipolar plates project.

2022

Developed and undertook the Continental automotive brake circlip project.

2022

Developed and undertook the elevator display and button panel project of KONE, Thyssen and Hitachi.

2023

Developed and undertook the Apple computer TP series laser welding module project, put into laser equipment.

2023

Developed and undertook the Yutong automobile electronic control sealed aluminum cover plate project, put into the air tightness testing equipment. At the same time, won the "Jiangsu Private Science and Technology Enterprise Honor" recognition which laid a good foundation for further development.

2023

Set up a sheet metal business department, with the ability to undertake the production/assembly of less quantified and customized products.

2023

Obtained high-tech enterprise qualification certification from the local government.

Our Team

The seamless collaboration between our Research and Development, Production, Quality Assurance, and Management departments is the driving force behind our commitment to providing exceptional products. Through collective efforts, we aim to exceed customer expectations, ensuring both product excellence and maximum satisfaction.