Hydrogen Energy Reactor

Precision Metal Stamping Specialist

Hydrogen Energy Reactor

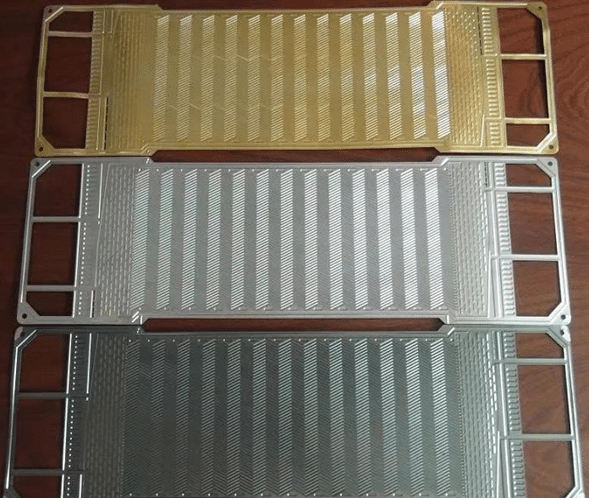

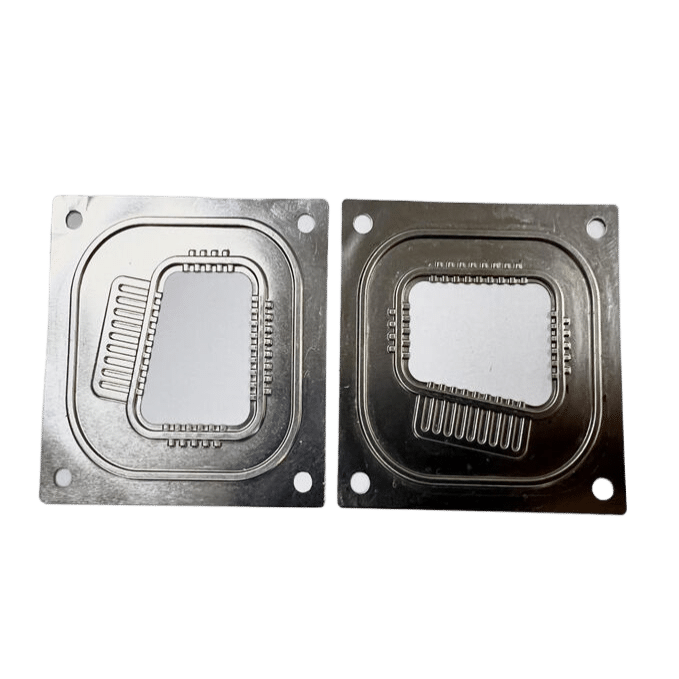

The production of metal components for hydrogen fuel cells involves precision engineering to meet the rigorous demands of fuel cell systems. Employing advanced metal stamping techniques, the process ensures the creation of intricate and high-performance parts vital for efficient hydrogen energy conversion. This production is characterized by precision fabrication, focusing on the intricate specifications necessary for the integration of fuel cell components. Commonly using materials such as stainless steel 316L, titanium alloys and nickel alloys for their corrosion resistance and durability, the manufacturing process emphasizes quality and reliability. Surface treatments, including specialized coatings and plating, are applied to enhance the components’ resistance to environmental factors. The production of metal parts for hydrogen fuel cells is a critical step in advancing clean energy technologies, contributing to the development of sustainable and efficient power sources.

Stamping Materials Used

- Titanium Alloy

- Stainless Steel 316L

- Nickel Alloy, etc.

Stamping Surface Treatment

- Surface Coating, etc.

Features

Product features: High-temperature resistance, corrosion resistance, excellent hydrogen gas sealing. Production characteristics: Precise dimensional requirements, strict gas tightness and material purity requirements. Special requirements: Knowledge of hydrogen energy technology, and corrosion resistance testing.

Finished Products Gallery

This is the heading