Busbar

Precision Metal Fabrication Specialist

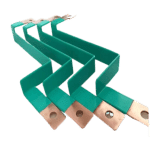

Busbar

The production of copper and aluminum busbars for power transmission equipment involves precision manufacturing to ensure reliable electrical conductivity and thermal performance. Utilizing advanced stamping technology, these components are produced in high volumes with a focus on efficiency and durability. Copper and aluminum, chosen for their excellent conductivity, are the primary materials used. The manufacturing process involves precise shaping and stamping to meet the specific requirements of power transmission systems. Surface treatments such as tin-plating and silver-plating are applied to enhance corrosion resistance and ensure long-term reliability. This production process plays a crucial role in the creation of robust busbars that form the backbone of efficient power distribution, supporting the reliable transmission of electricity across various applications and industries.

Stamping Materials Used

- Copper (3.0-6.0)

- Aluminum Alloy (3.0-6.0), etc.

Stamping Surface Treatment

- Electroplating

- Anodization

- Salt Spray Test 48 Hours

- Polishing, etc.

Features

Product features: Good conductivity and excellent heat dissipation performance. Production characteristics: Large size, multiple processes, high requirements for surface flatness. Special requirements: Electrical engineering knowledge, conductivity testing.