Precision Die Series

Precision Metal Fabrication Specialist

Home > Capabilities > Precision Die Series

Precision Die Series

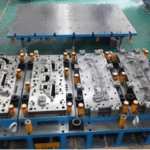

PenJing has been crafting intricate progressive dies from the very inception of our business. Although our capabilities have grown, our core expertise remains in the creation of progressive dies tailored to meet your most exacting requirements for precision metal stamping.

Whether the mould purchased before cause you trouble? Our internal processes are designed to address any issues you may have encountered. Starting with a meticulous examination of your drawing specifications and culminating in a pre-production trial at our facility, we will provide you with a production-ready progressive die that boasts quality and ease of maintenance, every single time. We can adhere to your existing progressive die design standards or our professional concept as the design standard.

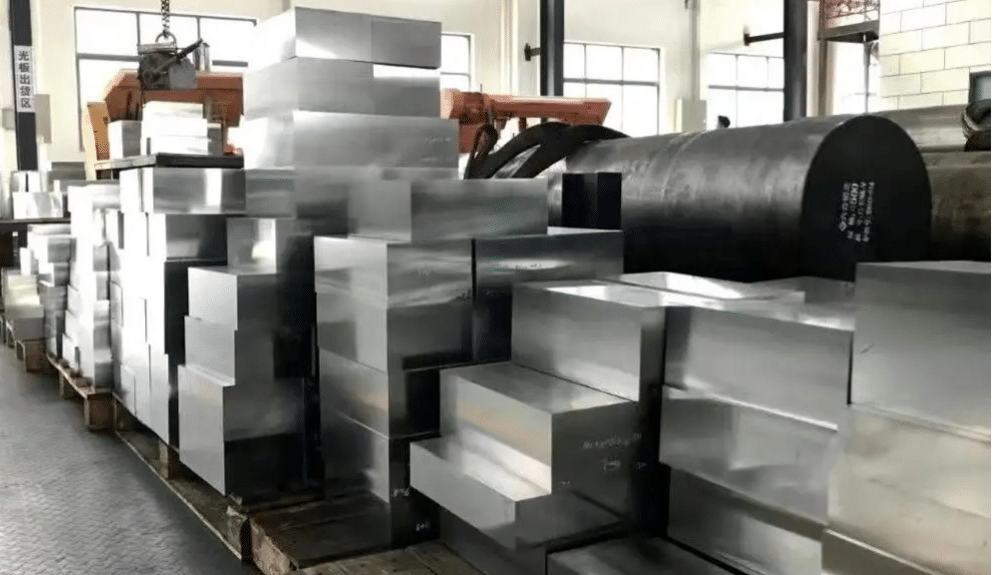

Die Materials Used

- Carbon Steel 45#/P20

- CR12/CR12MOV/D2/SKD11/DC53

- Cr12M SKD11/DC53/8566/PM23

- SKH-9/S690

- Tungsten Steel

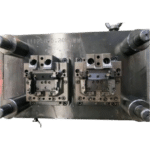

Die Maintenance Service

Our in-house team specializes in the meticulous care of progressive dies. This includes making die history to do regular maintenance, sharpening and shimming cutting components, refining and polishing form stations, verifying alignment and clearances, and, upon request, replacing any worn or damaged parts. Additionally, we can run your tool on one of our presses for testing. All parts undergo thorough inspection in our quality department, with detailed records kept for your reference. We’re also equipped to offer suggestions that may enhance the lifespan and performance of your die.

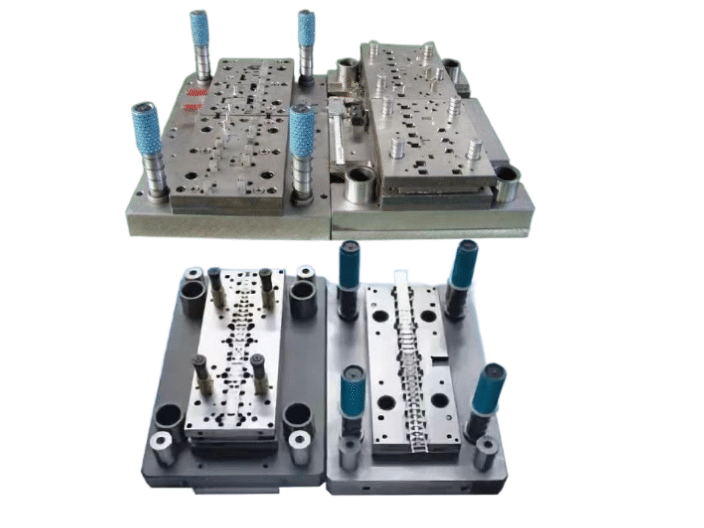

Common Die Types

- Progressive Dies: These dies are used for high-volume production of intricate parts. They consist of multiple stations, each performing a specific operation as the material passes through the die in a continuous strip. Progressive dies are efficient for mass production.

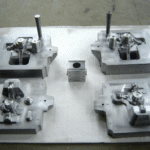

- Single-Station Dies: Also known as single-operation dies, these are used for simple operations like punching, blanking, or forming. Each part is produced individually, making them suitable for low to medium-volume production.

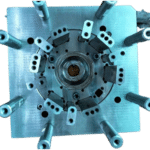

- Compound Dies: These dies can perform two or more operations simultaneously on a single press stroke. They are useful for parts that require multiple operations but do not justify the use of a progressive die.

- Transfer Dies: Transfer dies are used for complex parts with multiple operations. They transfer the workpiece from one station to another within the die for each operation. They are suitable for high-precision and high-volume production.

- Blanking Dies: These dies are designed for cutting flat shapes from a metal sheet. They are commonly used to produce parts like washers, gaskets, and electronic components.

- Piercing Dies: Piercing dies create holes or openings in the workpiece, such as those found in electrical enclosures, automotive parts, and structural components.

- Drawing Dies: Drawing dies are used to transform flat sheets of metal into cylindrical or cup-shaped components, such as beverage cans or automotive body panels.

- Embossing Dies: These dies are used to add decorative or functional patterns to metal surfaces, such as logos, textures, or serial numbers.

- Forging Dies: Forging dies are specialized tools used in the forging process to shape metal through the application of force, often used in the production of industrial machinery, tools, and automotive parts.

- Trimming Dies: Trimming dies are employed to remove excess material or flash from a formed or molded part, ensuring a clean and precise final product.

- Bending Dies: Bending dies are used to create bends and angles in sheet metal, commonly found in applications like HVAC ductwork and metal furniture.

- Extrusion Dies: These dies are utilized in the extrusion process to create continuous profiles or shapes by forcing material through an opening, as seen in the production of aluminum window frames or PVC pipes.

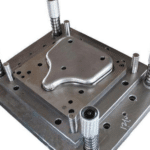

- Forming Dies: Forming dies are used to shape metal into desired contours, often used in industries like aerospace and automotive for components with complex geometries.